Adding weight to empty rolling stock can help to improve their running smoothness and reduce the risk of derailing on...

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Search Tips

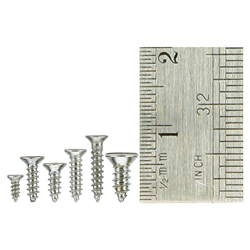

What is a countersunk screw?

A countersunk screw is a type of fastener that is designed to sit flush with or below the surface of the material it is driven into. The head of the screw is conical, tapering down to a flat or slightly rounded top, allowing it to sink into a countersunk hole and create a smooth finish. This type of screw is particularly useful in applications where a neat and streamlined appearance is desired, or where the screw head should not protrude and interfere with the surrounding surfaces.

In the context of scale modelling, countersunk screws are often used to securely fasten different components together without disrupting the detailed finish of the model. Whether you are assembling parts of a miniature vehicle, aircraft or architectural structure, using countersunk screws allows for a cleaner and more realistic look. For example, in model aircraft, exposed screws could detract from the smooth lines of a fuselage, so countersinking helps maintain the model's aesthetic accuracy.

Countersunk screws are also favoured for their practicality in scale modelling because they reduce the need for additional work, such as sanding or covering protruding heads, before painting or applying decals. They can provide structural integrity while maintaining the precision and delicate appearance crucial to detailed models, particularly in high-precision builds where even the smallest imperfections are noticeable.

Click here to receive the tips weekly in your mailbox. You can unsubscribe at any time.