The Great Western Railway's Garter Crest is just one of the many logo designs to have appeared on GWR locomotives and...

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Search Tips

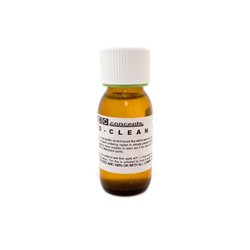

What are the benefits to be gained from using flux when I am soldering ?

Flux is a crucial component in the soldering process, and using it offers several benefits that improve the quality and reliability of solder joints. Flux is a chemical compound that helps to clean and prepare the surfaces being soldered, as well as enhance the flow of solder.

Here are some of the key benefits that can be gained from using flux:

- Cleans and removes oxides : flux helps to remove oxides and other contaminants from the surfaces being soldered. Oxides can form on metal surfaces due to exposure to air, moisture, or heat and they can hinder the solder's ability to bond properly. Flux acts as a cleaning agent, dissolving these oxides and ensuring a clean surface for the solder to adhere to.

- Promotes solder flow : flux improves the flow of solder by reducing surface tension. When flux is applied to the solder joint, it helps the solder to spread evenly and smoothly over the surfaces, creating a strong and reliable bond. This is especially important when soldering small or intricate components, as flux ensures that the solder reaches all the necessary areas.

- Prevents oxidation during soldering : flux creates a protective barrier on the solder joint, preventing oxidation during the soldering process. Oxidation can occur when the heated metal comes into contact with air, leading to weakened solder joints. By using flux, it is possible to minimise the risk of oxidation and ensure a more durable connection.

- Ensures stronger and more reliable joints : the use of flux results in stronger and more reliable solder joints. By removing oxides, promoting solder flow and preventing oxidation, flux helps to create a solid bond between the solder and the surfaces being joined. This leads to improved electrical conductivity and mechanical strength, reducing the chances of joint failure.

It's important to note that different types of flux are available, such as rosin-based flux, water-soluble flux and no-clean flux. Each type has its own specific application and characteristics, so it is essential to choose the flux that is best suited to the task at hand.

In summary, using flux when soldering provides several benefits, including cleaning and removing oxides, promoting solder flow, preventing oxidation and ensuring stronger and more reliable joints. By incorporating flux into the soldering process, it is possible to achieve better results and enhance the overall quality of the soldered connections.

Click here to receive the tips weekly in your mailbox. You can unsubscribe at any time.