Hornby's curved platform sections feature on many home layouts, and although there are arguably more realistic...

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Search Tips

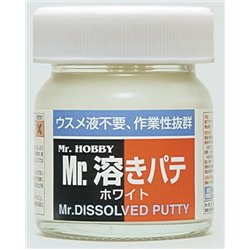

What is meant by the term 'Sprue Goo' and how can it be used ?

Sprue Goo is an interesting concept used by modellers across a wide range of modelling subjects. The process uses the leftover plastic sprues from a completed model and a suitable solvent, such as extra thin glue.

A number of manufacturers create their own version of extra thin glue for use on plastic models. Many of these glues are supplied in small bottles of approximately 40ml and are often supplied with an applicator brush on the inside of the lid. The problem comes when the bottles are more than half empty as it is more difficult for the brush to reach the remaining glue within the bottle.

At this point many modellers will either refill the bottle or use a different full bottle. It is at this 'half empty' stage however that the bottle is in an ideal condition to fill a slightly more unusual role. If at this point the modeller fills the bottle with sections of sprue as opposed to topping up with more glue they can effectively create their own d.i.y model filler.

To create 'Sprue Goo', simply cut sections of redundant plastic sprue into sections of 5-10mm and add it to the glue in the bottle. Over the course of approximately one hour the glue will act as a solvent and chemically melt the plastic sprue into a form of sticky plastic putty. The consistency of the resultant Goo will be dependent on the amount of sprue sections added. For a thicker solution more sprue is added, conversely for a thinner solution less sprue is needed.

The resultant goo has a consistency that allows it to be easily worked, is sticky and can be easily applied by the brush attached to the inside of the lid. The resultant Goo is then ideally applied as a filler or for beefing up and reinforcing delicate joints for which extra thin adhesive would be impractical.

Both small sections of sprue or sprue shavings cut with a hobby knife are ideal for the task. In addition to extra-thin glue, small amounts of paint thinner or acetone will provide a similar chemical reaction. This will result in a plastic material with putty like consistency that is both forgiving and can easily be worked and applied by a paintbrush, toothpick or spatula as is most appropriate.

Whilst creating 'Sprue Goo' it is important to bear in mind that the solvents in use will produce harmful vapours if inhaled, so it is important to work in a well ventilated environment.

Click here to receive the tips weekly in your mailbox. You can unsubscribe at any time.