It's not very often that it happens, but occasionally you may get a DCC locomotive that runs in the opposite...

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Search Tips

How do I increase pulling power on gradients?

There are several ways to improve traction on those steep gradients. Below are a few ways to try.

Consist: This method uses two or three engines joined together in a row. This is what is done in real life to pull very heavy loads. This is very frequent in the USA.

Adding weight: By adding weight to your locomotive, you will help to keep the engine firmly on the track helping with extra traction.

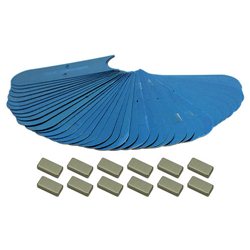

Traction tyres: Adding traction tyres to your locomotives will help to get that extra traction needed. They are a bit fiddly to fit but once on will do the job. Not all engines can be fitted with tyres and sizes vary a lot. Obviously, this does not look proto-typical.

PowerBase: It works by placing metal plates under the track and magnets glued under the engines. The magnets are drawn to the plates and puch the engine to the rails, which will allow for maximum traction up that slope. This is manufactured by DCC Concept and available from model shops.

Click here to receive the tips weekly in your mailbox. You can unsubscribe at any time.